Staple System Awnings can utilize any type of fabric and be manufactured in almost any design allowing total product flexibility. They are considered to be a manufacturer friendly awning system because the fabric cover does not have to be manufactured with exacting precision so it fits an existing fixed frame. Rather fabric can be cut from the roll, stapled into the channel of the framework, excess fabric trimmed and PVC insert applied. These awnings are typically manufactured and delivered to the job site with the covers fitted. Because the covers are already attached to the frame at installation, Z Brackets are used for mounting and can be located anywhere on the awning where framework touches the wall.

Staple System Awnings can utilize any type of fabric and be manufactured in almost any design allowing total product flexibility. They are considered to be a manufacturer friendly awning system because the fabric cover does not have to be manufactured with exacting precision so it fits an existing fixed frame. Rather fabric can be cut from the roll, stapled into the channel of the framework, excess fabric trimmed and PVC insert applied. These awnings are typically manufactured and delivered to the job site with the covers fitted. Because the covers are already attached to the frame at installation, Z Brackets are used for mounting and can be located anywhere on the awning where framework touches the wall.

Although Staple System Awnings are manufacturer friendly, they are not always considered to be building code friendly and can be an issue in areas where cover removal for extreme wind or snow conditions are necessary. Once the cover is removed (cut away), new fabric must then be installed due to the inherent design of the framework.

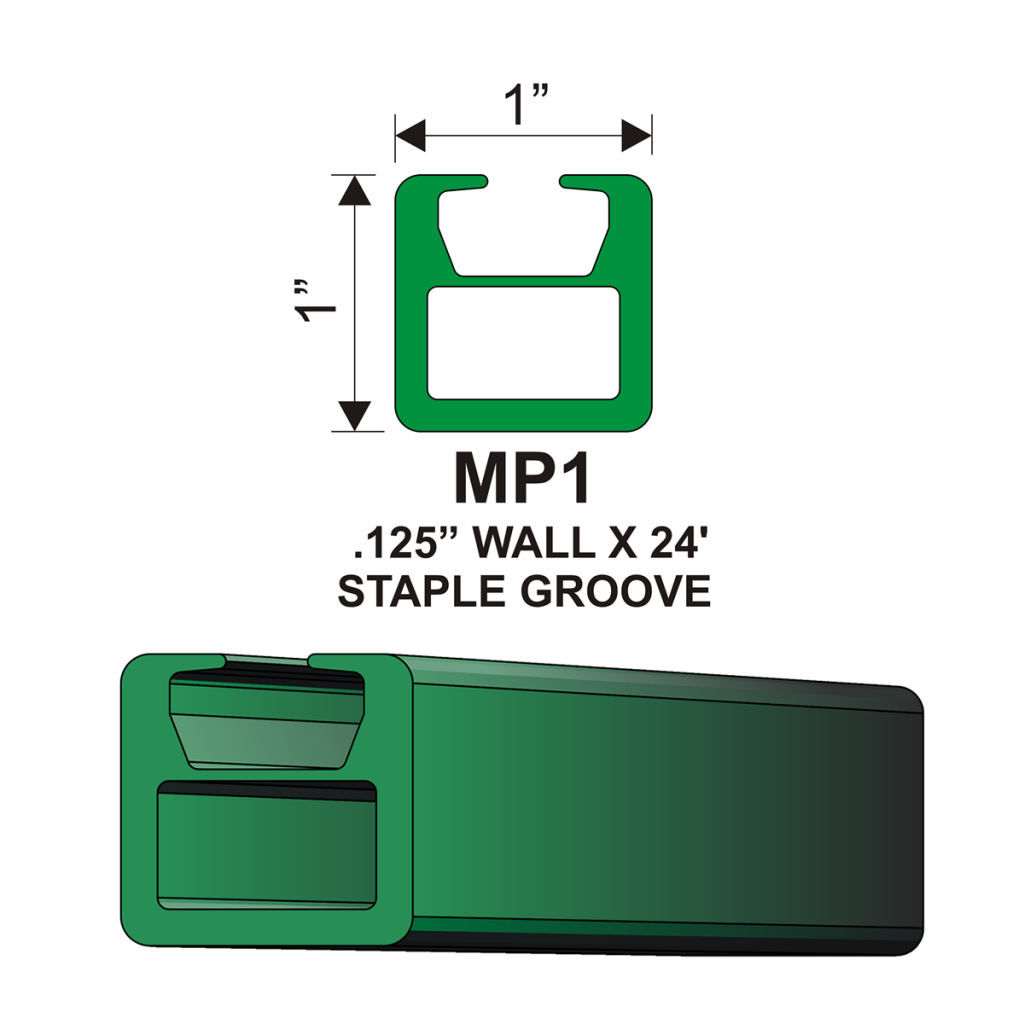

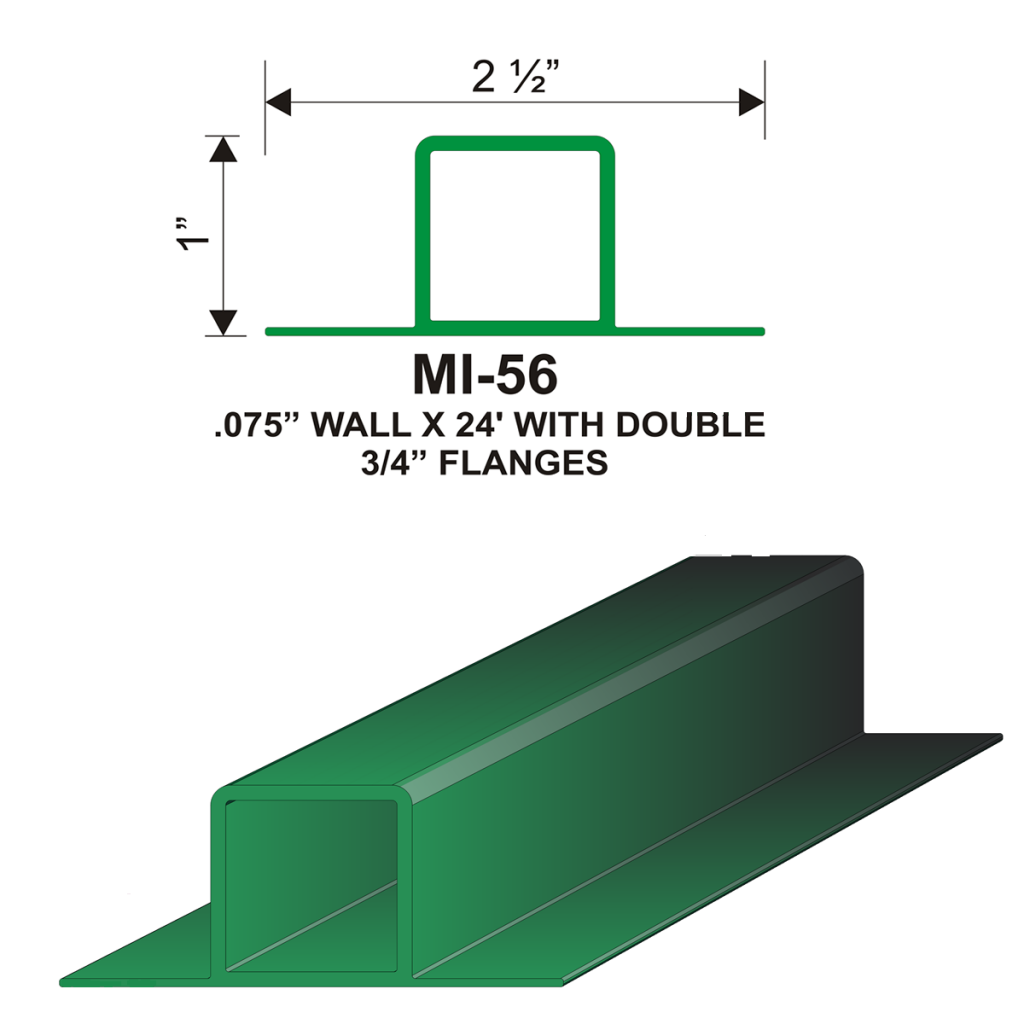

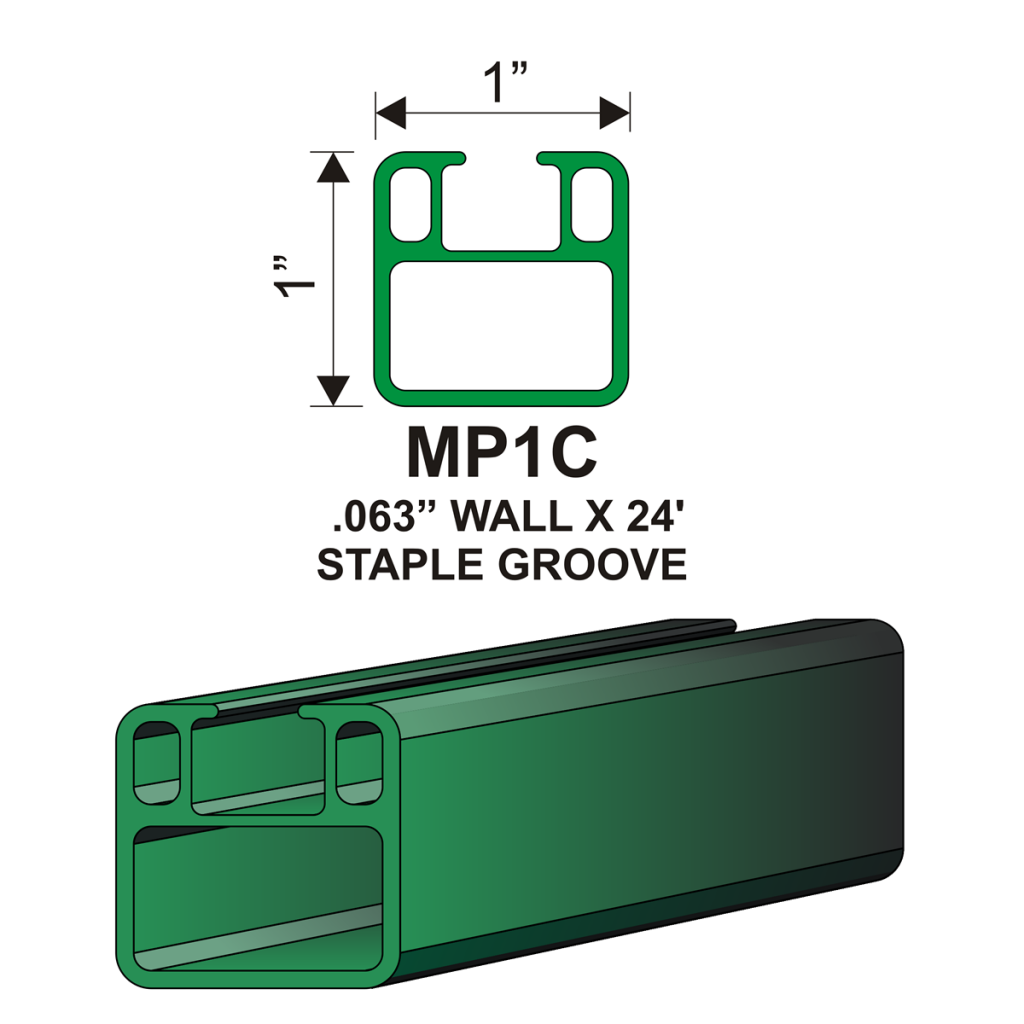

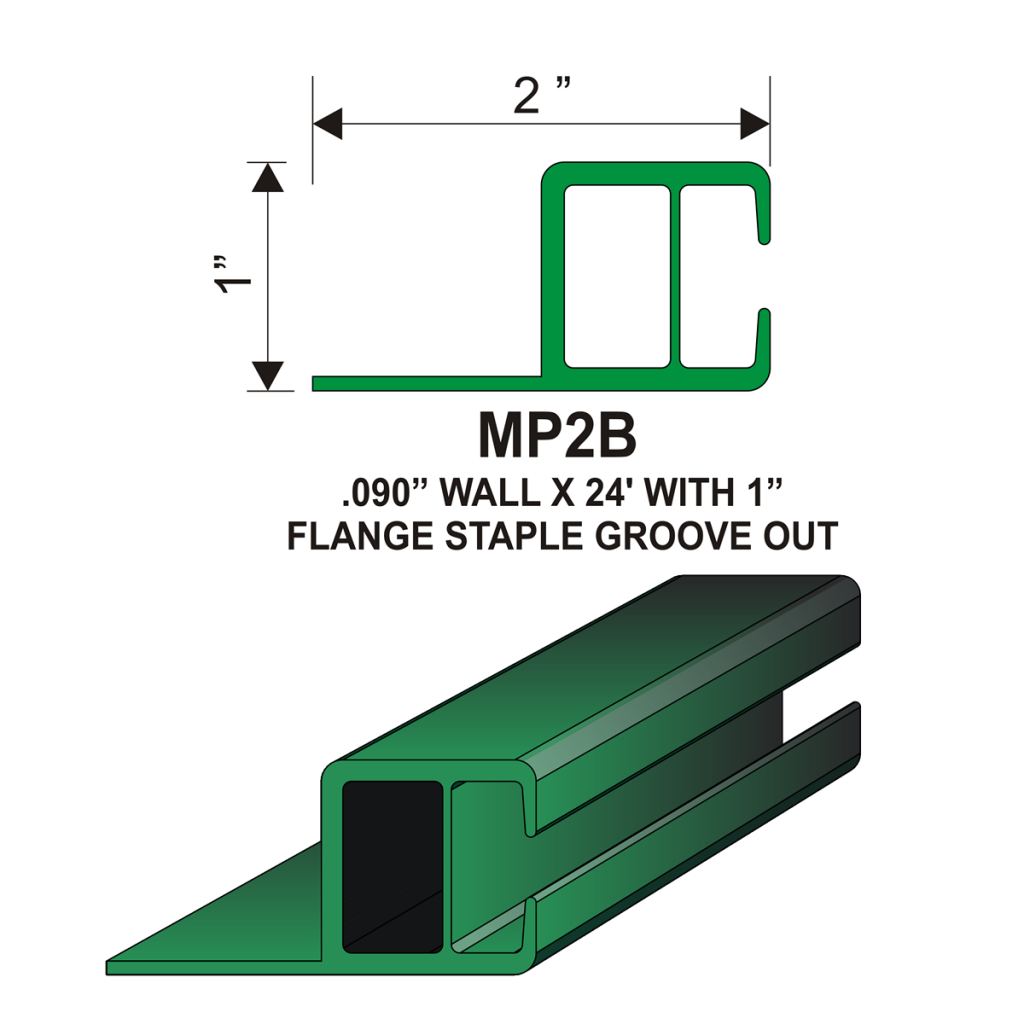

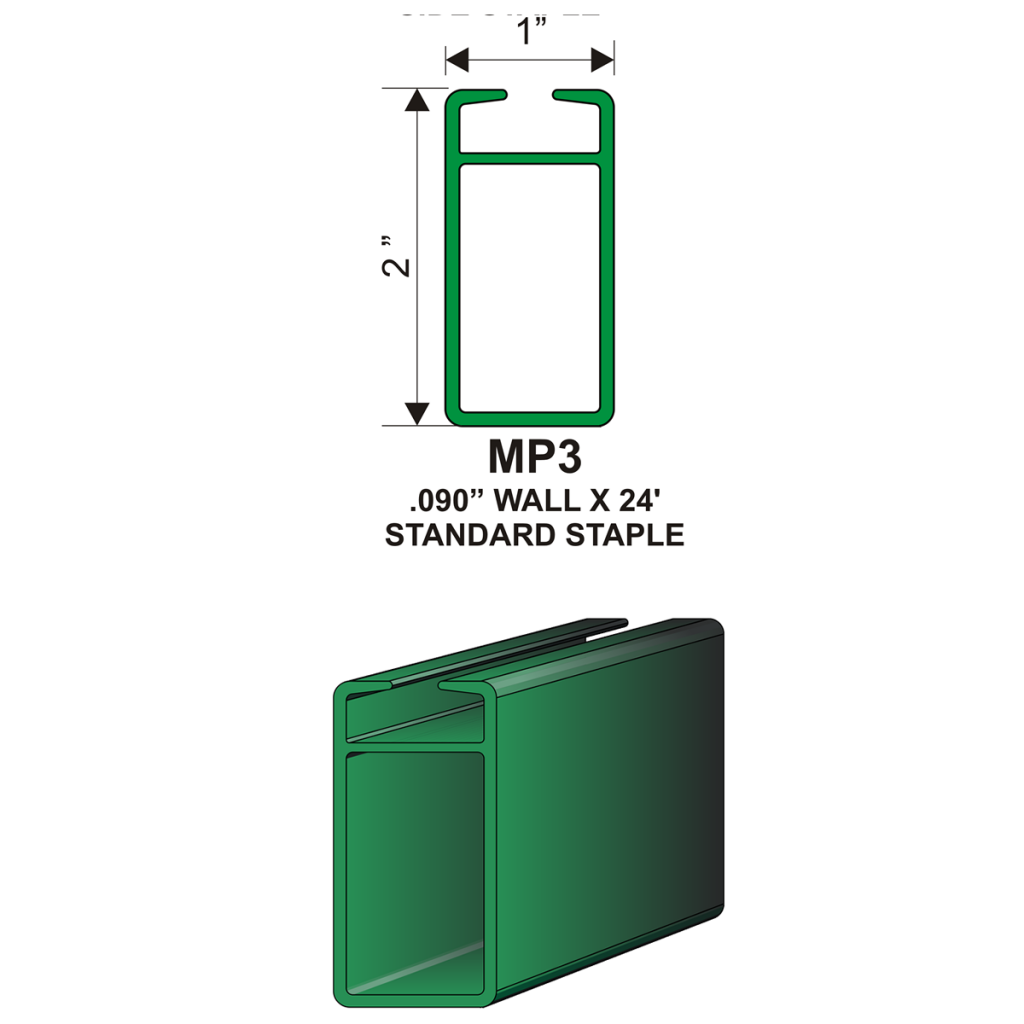

Most staple system extrusions are available in sizes as small as 1”x1” and as large as 2”x2”. The base metals are either aluminum or galvanized steel. The shapes in which the extrusions are available in may differ slightly from one supplier to another but remain the same in concept. Extrusions with a flange are typically used at the bottom of the awning to support egg crating which allows the awning to breathe, light the be transmitted at night and keeps bird from making nests inside the awning. Below are some examples of staple system extrusions: